SIMTRUM is professional in setting up laser processing related application, if you have any question related to laser processing setup, We are happy to talk to you. Contact us or Email to: info@simtrum.com

Resistor Trimming Material Copper Nickle Alloy

For the backend IC manufacturing, manufacturers uses laser resistor trimming technique to burn away part of the resistor structure using a laser beam of wavelength 1064nm, 532nm or 355nm. As the resistor's effective cross-section is reduced, resistance increases.

Usually, there are a few key influencing factors that need to be taken into consideration for different applications, depending on the result you want to achieve, below are only some of the guidance.

| Cost | Trimming Result |

Wavelength 1064 | Low | It uses heat to burn the material so it has a crater effect, cutting street is wide, for those processes that don't require precision trimming, this is good enough. |

Wavelength 532 | Medium | With different pulse width and cutting times, it can achieve a non-crater effect on the samples, and at the same time minimize the cutting street width. |

Wavelength 355 | High | It gives a clean cut on samples that don't have the crater effect, and the cutting street is able to achieve 10um or even lower. |

In the end, customers need to balance the trimming result and cost for choosing the right solution, below are the resistor testing result by using our DPSS Q-Switch ns Laser.

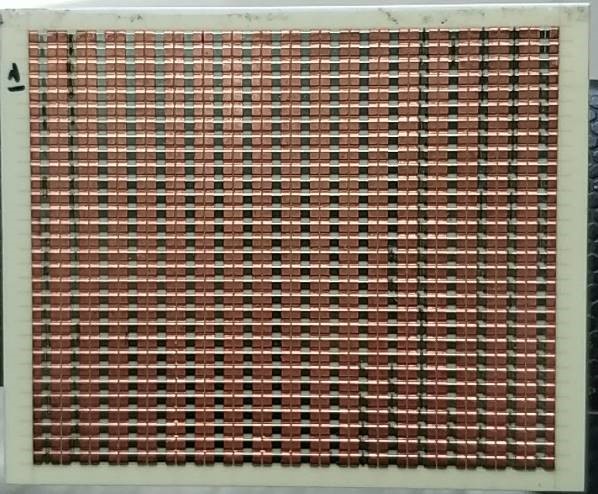

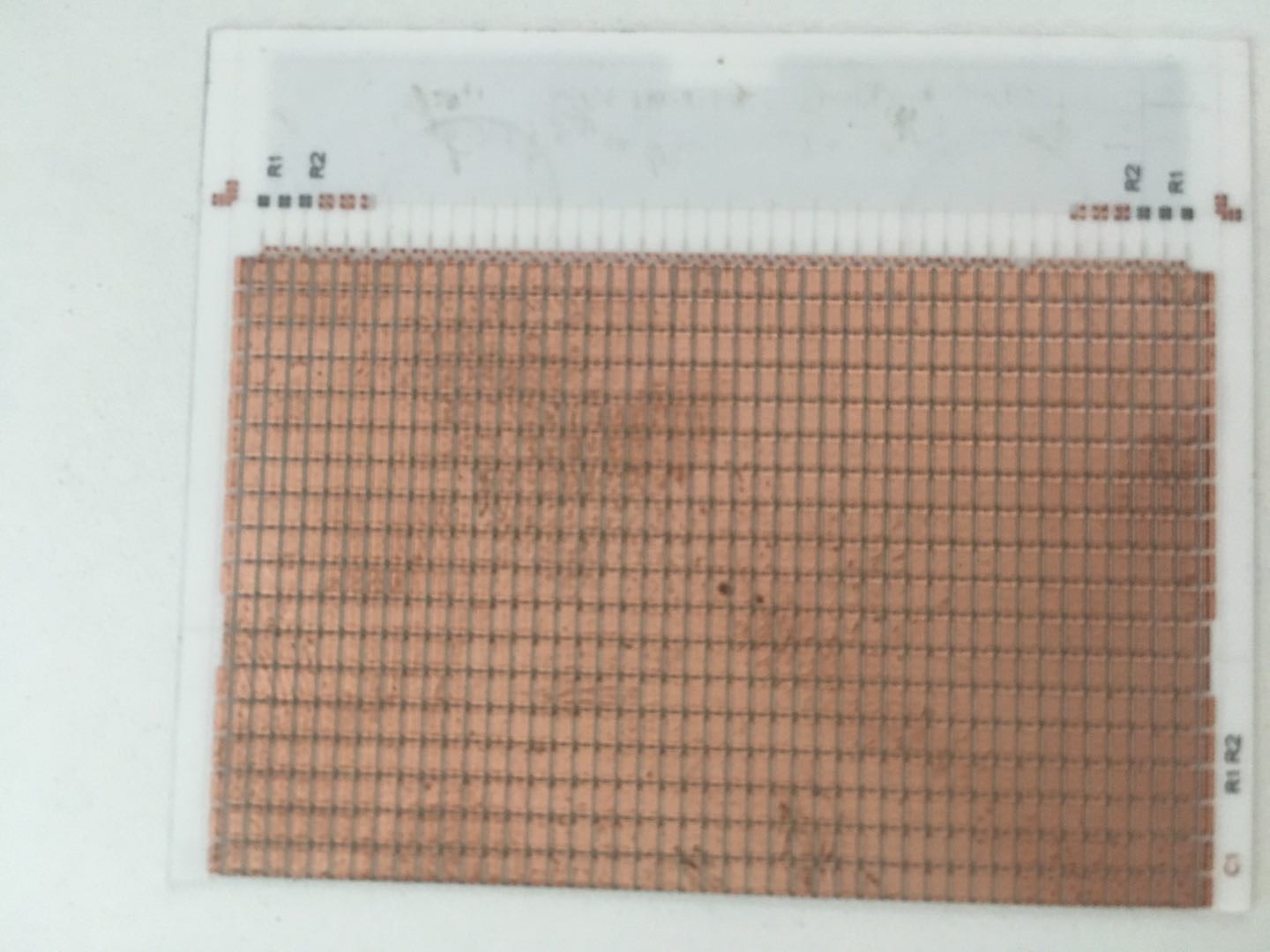

Testing samples

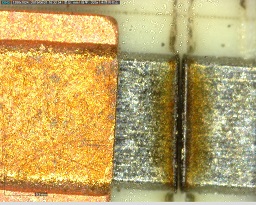

Thick Resistor Thin Resistor

Street width 0.9mm, Thickness 0.071mm Street width 0.2mm, Thickness 0.02mm

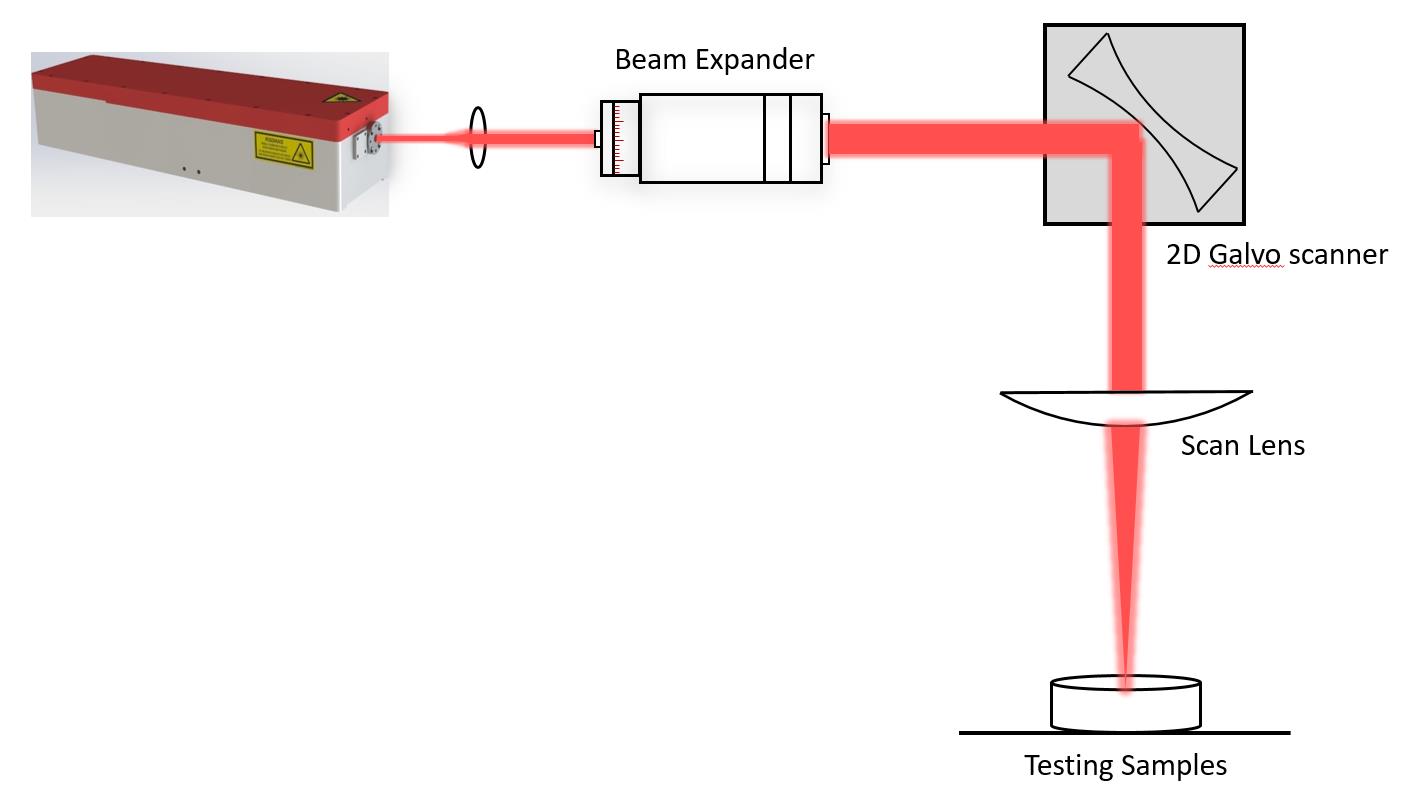

1064nm Laser System Setup

7W Nd: YAG 1064nm Beam expender: 8X; Scan lens: f160mm

Customer Requirement: Minimize the crater effect on sample

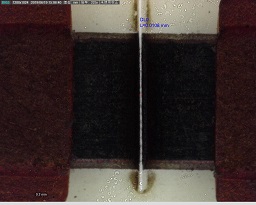

Thick Sample Result (20um Street width, with crater effect)

Rep Rate: 16KHZ; Speed: 130mm/s; Cutting Times: 60times; Delay times: 500ms/cut

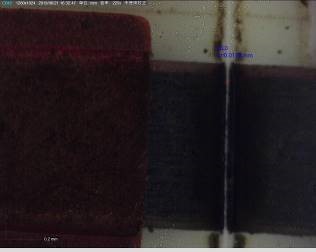

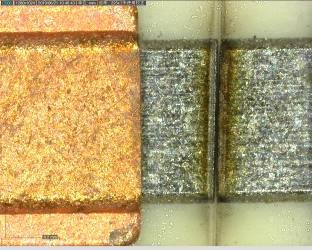

Back Front

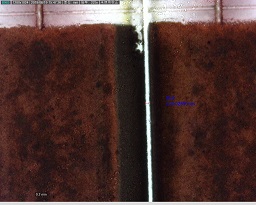

Rep Rate: 40KHZ; Speed: 400mm/s; Cutting Times: 100times; Delay: 300ms/cut

Note: We increase the scanning speed and cut for more times, the cutting street width reduces to 17um and the crater effect is not so serious.

Back Front

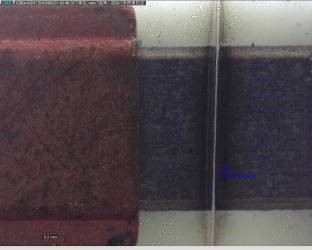

Thin Sample Result (28um Street width, with minimum crater effect)

Rep Rate:40KHZ; Speed:400mm/s; Cutting Times:40times; Delay:300ms/cut

Back Front

532nm Laser System Setup

8W 532 laser Beam expender: 8X; Scan lens: f100mm

Customer Requirement: Minimize cut times while reducing the crater effect on sample

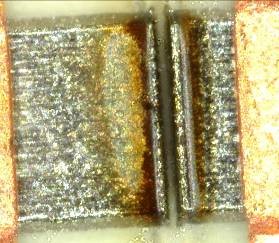

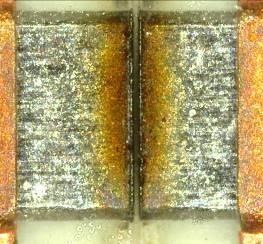

Thick Sample Result: (19.4um Street width, with crater effect due to low cutting times)

Rep rate: 40khz, Pulse width: 10.2ns, Pulse energy: 218.25uJ, Peak power: 21.4KW, Speed:160mm/s, Cutting times:15

Back Front

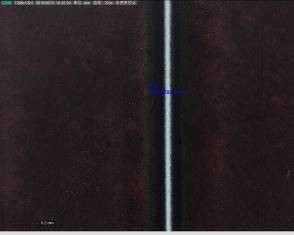

Thin Sample Result: (21.5um Street width, with small crater effect)

Laser setting: Rep rate: 50khz, Pulse width: 10.7ns, Pulse energy: 181.6uJ, Peak power: 16.97KW, speed:60mm/s, Cutting times: 2

Back Front

355nm Laser System Setup

10W 355 laser Beam expender:8X; Scan lens: f63mm

Customer requirement: narrow cut street and no crater effect

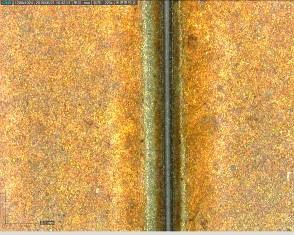

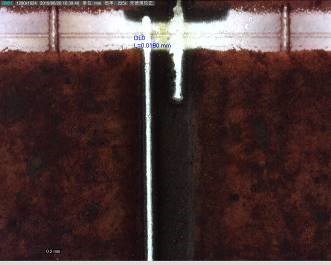

Thick Sample (10um Street width, with no crater effect)

Rep Rate:50khz, Speed:500mm/s; Times:20times;

Back Front

Thin Sample (19um Street width, with no crater effect)

Rep Rate:60khz, Speed:600mm/s; Times:10times; Delay:300ms;

Back Front

Conclusion

DPSS 1064nm Nanosecond laser can achieve the result with wide cutting street and crater effect, we can reduce the power with more cuts to improve the cutting street and crater effect.

DPSS 532nm Nanosecond laser customer request to minimize the cutting times, for thick sample we manage to cut through the sample in 2 cuts. Ideally, if more cutting times and lower power applied, the cutting street width and crater effect can be minimized.

DPSS 355nm Nanosecond laser provides the most effective cutting speed, and by using a short focal lens the result is the best, the cutting line is within 10um with no crater effect, but the cost of 355nm laser is higher.