Line Scan Hyperspectral Camera (220nm-4.2um)

| Compare |

Model |

|

Drawings & Specs |

Availability |

Reference Price

(USD) |

|

|

|

|

BlueEye UV STD (220 – 380 nm)

Wavelength Range 220 – 380 nm , Passive cooling, 2048 x 2048 Pixel, 40FPS, Spectral Resolution <2nm

|

|

6 - 10 Weeks |

Request for quote |

|

|

|

|

BlueEye UV TEC (220 – 380 nm)

Wavelength Range 220 – 380 nm , TEC cooling -25 degrees, 2048 x 2048 Pixel, 40FPS, Spectral Resolution <2nm

|

|

6 - 10 Weeks |

Request for quote |

|

|

|

|

BlueEye UV Scientific (220 – 380 nm)

Wavelength Range 220 – 380 nm , 4XTEC cooling -100 degrees, 1056 x 1027 Pixel, 5FPS, Spectral Resolution <1nm

|

|

6 - 10 Weeks |

Request for quote |

|

|

|

|

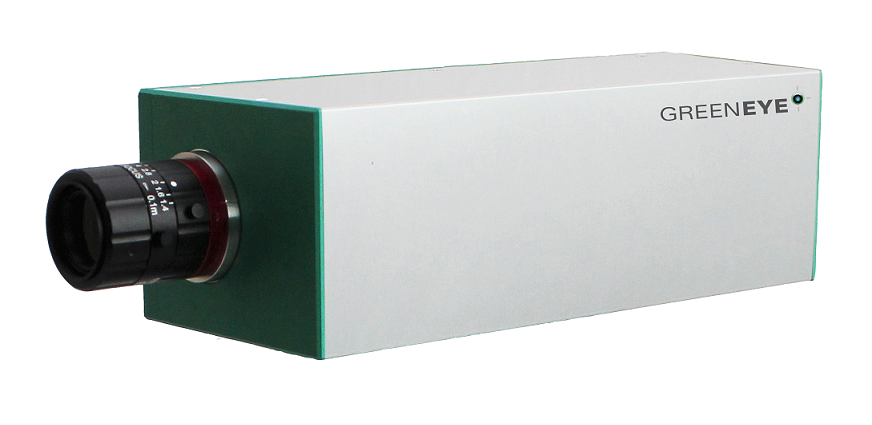

GreenEye Hyperspectral Camera (400-1000nm)

Wavelength Range 400-1000nm 1312 x 1082 Pixel, up to 54 FPS, Spectral Resolution 10 nm

|

|

4-6 Weeks |

Request for quote |

|

|

|

|

OrangeEye Hyperspectral Camera (580-1000nm)

Wavelength Range 580-1000nm 1312 x 1082 Pixel, up to 54 FPS, Spectral Resolution 10 nm

|

|

4-6 Weeks |

Request for quote |

|

|

|

|

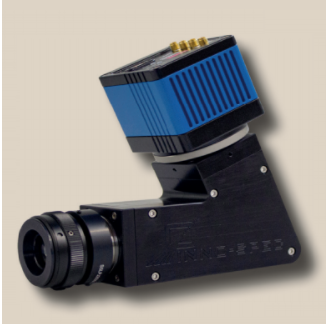

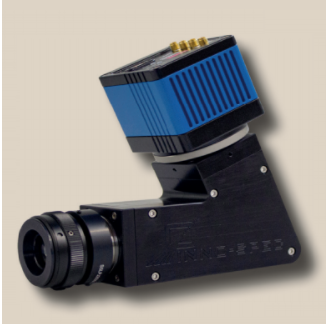

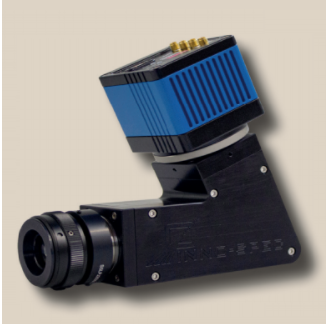

NIR Hyperspectral Camera STD (950 to 1700nm)

Wavelength Range 950 to 1700 nm, 320 x 256 Pixel, up to 4200 FPS, Spectral Resolution 10 nm

|

|

4-6 Weeks |

Request for quote |

|

|

|

|

NIR Hyperspectral Camera HiRes (950 to 1700nm)

Wavelength Range 950 to 1700 nm, 640 x 512 Pixel, up to 4200 FPS, Spectral Resolution 10 nm

|

|

4-6 Weeks |

Request for quote |

|

|

|

|

NIR Hyperspectral Camera RGB (950 to 1700nm)

Wavelength Range 950 to 1700 nm, 320 x 256 Pixel, up to 4200 FPS, Spectral Resolution 10 nm, Additional RGB information in the same beam path

|

|

4-6 Weeks |

Request for quote |

|

|

|

|

NIR Hyperspectral Camera EXT (1200 to 2200nm)

Wavelength Range 1200 to 2200nm, 320 x 256 Pixel, up to 3300 FPS, Spectral Resolution 13 nm

|

|

4-6 Weeks |

Request for quote |

|

|

|

|

MIR Hyperspectral Camera (2900 – 4200 nm)

Wavelength Range 2900 – 4200 nm 320 x 256 Pixel, up to 383 FPS, Spectral Resolution 18 nm

|

|

4-6 Weeks |

Request for quote |

|

RGB/LED lighting - Parameter

Halogen light bar Option - Parameter

MIR light bar 1 m - Parameter

White reference (Spectral on 50x20cm) - Parameter

Speccer Basic - Parameter

NIR Len C-Mount - Parameter

VIS Len C mount - Parameter

UV 35 mm F/2.8 1/2" C-Mount - Parameter

VIS-NIR Len C-Mount - Parameter

MIR Hyperspectral Camera (2900 – 4200 nm) - Parameter

NIR Hyperspectral Camera EXT (1200 to 2200nm) - Parameter

NIR Hyperspectral Camera RGB (950 to 1700nm) - Parameter

NIR Hyperspectral Camera HiRes (950 to 1700nm) - Parameter

NIR Hyperspectral Camera STD (950 to 1700nm) - Parameter

OrangeEye Hyperspectral Camera (580-1000nm) - Parameter

GreenEye Hyperspectral Camera (400-1000nm) - Parameter

BlueEye UV Scientific (220 – 380 nm) - Parameter

BlueEye UV TEC (220 – 380 nm) - Parameter

BlueEye UV STD (220 – 380 nm) - Parameter

RGB/LED lighting - Download

Halogen light bar Option - Download

MIR light bar 1 m - Download

White reference (Spectral on 50x20cm) - Download

NIR Len C-Mount - Download

VIS Len C mount - Download

UV 35 mm F/2.8 1/2" C-Mount - Download

VIS-NIR Len C-Mount - Download

MIR Hyperspectral Camera (2900 – 4200 nm) - Download

NIR Hyperspectral Camera EXT (1200 to 2200nm) - Download

NIR Hyperspectral Camera RGB (950 to 1700nm) - Download

NIR Hyperspectral Camera HiRes (950 to 1700nm) - Download

NIR Hyperspectral Camera STD (950 to 1700nm) - Download

OrangeEye Hyperspectral Camera (580-1000nm) - Download

GreenEye Hyperspectral Camera (400-1000nm) - Download

BlueEye UV Scientific (220 – 380 nm) - Download

BlueEye UV TEC (220 – 380 nm) - Download

BlueEye UV STD (220 – 380 nm) - Download

Accessories

| Compare |

Model |

|

Drawings & Specs |

Availability |

Reference Price

(USD) |

|

|

|

|

VIS-NIR Len C-Mount

VIS-NIR Len Focal Length 16mm, 25mm, 35 mm, 50mm

|

|

In Stock |

Request for quote |

|

|

|

|

UV 35 mm F/2.8 1/2" C-Mount

UV 35 mm F/2.8 1/2" C-Mount

|

|

In Stock |

Request for quote |

|

|

|

|

VIS Len C mount

VIS Len C mount Focal length option 5 mm & 25mm

|

|

In Stock |

Request for quote |

|

|

|

|

NIR Len C-Mount

NIR Len C-Mount Focal Length Option 8mm ,12mm, 16mm, 25mm, 35mm, 50mm, 75mm

|

|

In Stock |

Request for quote |

|

|

|

|

Speccer Basic

Speccer Basic

|

|

In Stock |

Request for quote |

|

|

|

|

White reference (Spectral on 50x20cm)

White reference (Spectral on 50x20cm)

|

|

In Stock |

Request for quote |

|

|

|

|

MIR light bar 1 m

Different dimensions available

|

|

In Stock |

Request for quote |

|

|

|

|

Halogen light bar Option

Halogen light bar Length option 0.5m, 1m ,1.5m or 2m

|

|

In Stock |

Request for quote |

|

|

|

.jpg) |

RGB/LED lighting

Flash sequence 2

|

|

In Stock |

Request for quote |

|