|

|

|

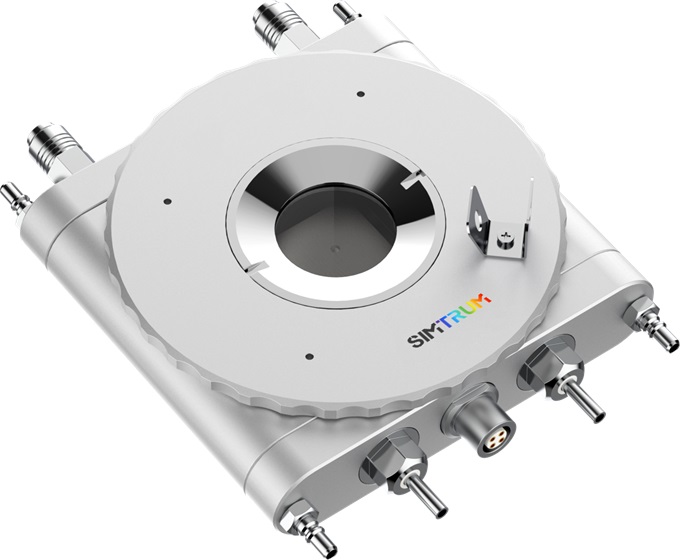

CRYO600-190

Optical Cryo & High Temperature Stage, Temp control range -190 to 600℃, Gas-tight Chamber, Loading platform: 23×23mm, Silver.Price includes: Temperature Stage and Controller, Chiller, LN2 Tank, Software.

|

|

8-12 Weeks |

$10344.00 |

|

|

|

.jpg) |

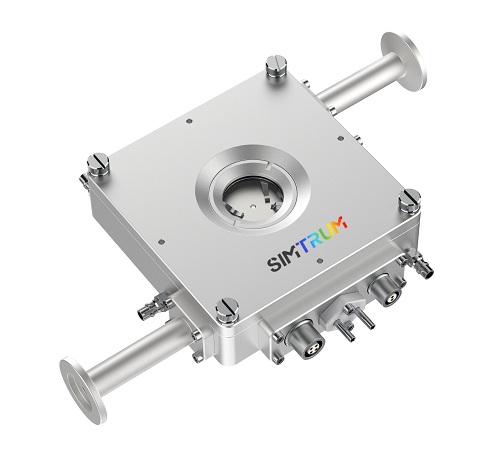

CRYO600-190-XY

Optical Cryo & High Temperature Stage, Temp control range -190 to 600℃, Gas-tight Chamber, Loading platform:23×23mm, silver.Displacement stroke ±6.5mm,Price includes: Temperature Stage and Controller, Chiller, LN2 Tank, Software.Vacuum chamber and visualization components can be upgraded.

|

|

8-12 Weeks |

$12425.00 |

|

|

|

|

RTH600

Optical Cryo & High Temperature Stage, Temp control range Room Temp to 600℃,Airtight chamber,Sample stage 23*23mm, Silver, stainless steel optional, Price includes: Temperature Stage and Controller, Water circulating system, Software.

|

|

8-12 Weeks |

$4758.00 |

|

|

|

|

RTH800

Optical Cryo & High Temperature Stage, Temp control range Room Temp to 800℃,Airtight chamber,Sample stage 23*23mm, Stainless steel, The top cover can be upgraded to water cooling.Price includes: Temperature Stage and Controller, Water circulating system, Software.

|

|

8-12 Weeks |

$5793.00 |

|

|

|

.jpg) |

RTH1000

Optical Cryo & High Temperature Stage, Temp control range RT to 1000℃, Stage 20*20mm, ceramic,Price includes: Temperature Stage and Controller, Water circulating system, Software.

|

|

8-12 Weeks |

$14404.00 |

|

|

|

.jpg) |

RTH1500

Optical Cryo & High Temperature Stage, Temp control range RT~1200℃/1500℃, Airtight chamber,Sample loading by crucible, crucible material optional ceramic, quartz, sapphire, etc., Price includes: Temperature Stage and Controller, Water circulating system, Software.

|

|

8-12 Weeks |

$19732.00 |

|

|

|

.jpg) |

RTH1800

Optical Cryo & High Temperature Stage, Temp control rangeRT~1800℃ or even higher

|

|

8-12 Weeks |

Request for quote |

|

|

|

.jpg) |

RTH1200

Optical Cryo & High Temperature Stage, Temp control range RT to 1200℃, Stage 20*20mm, ceramic,Price includes: Temperature Stage and Controller, Water circulating system, Software.

|

|

8-12 Weeks |

$16575.00 |

|

|

|

|

PE120-25

Optical Cryo & High Temperature Stage, Temp control range -25 to 120℃, 40*40mm sample stage, copper, Semiconductor heating, Price includes: Temperature Stage and Controller, Water circulating system, Software.

|

|

8-12 Weeks |

$4138.00 |

|

|

|

|

MINI RTH-200

Optical hot and cold stage, RT~250℃, no cavity, sample stage 20*20*4mm, price includes: mini hot stage, temperature controller, temperature control

|

|

8-12 Weeks |

$1655.00 |

|

|

|

|

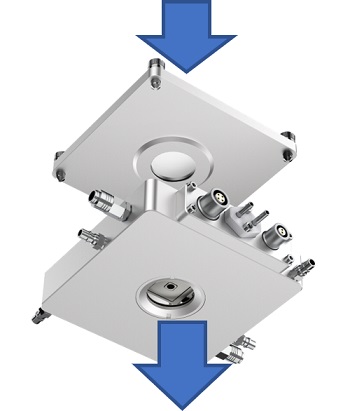

Vacuum Chamber Upgrade

Upgraded vacuum chamber and interface (KF16), Temperature range -190 to 400℃.

|

|

8-12 Weeks |

$1000.00 |

|

|

|

|

Transmission Stage Upgrade

Upgrade stage from Reflection to Transmission, Standard hole size 2mm

|

|

8-12 Weeks |

$500.00 |

|

|

|

|

Weak Magnetic Chamber Upgrade

Upgraded Weak Magnetic Chamber, Enhancing shielding effectiveness to address challenges of magnetic field noise.

|

|

8-12 Weeks |

$1500.00 |

|

|

|

|

Vertically oriented mounting

Upgraded stage for vertical mounting in spectroscopic or optical systems

|

|

In Stock |

$500.00 |

|