Project / Application Background

System Requirement

● Integrate laser system with the existing robotic arm ● Laser power out power 1000-2000W or higher ● The Laser focus spot is required to be a uniform rectangle: length 50mm * Width 5mm ● Constant temperature measure to adjust laser power to achieve uniform temperature ● Laser safety and monitoring system need to be implemented

|

Product Brochures Link

|

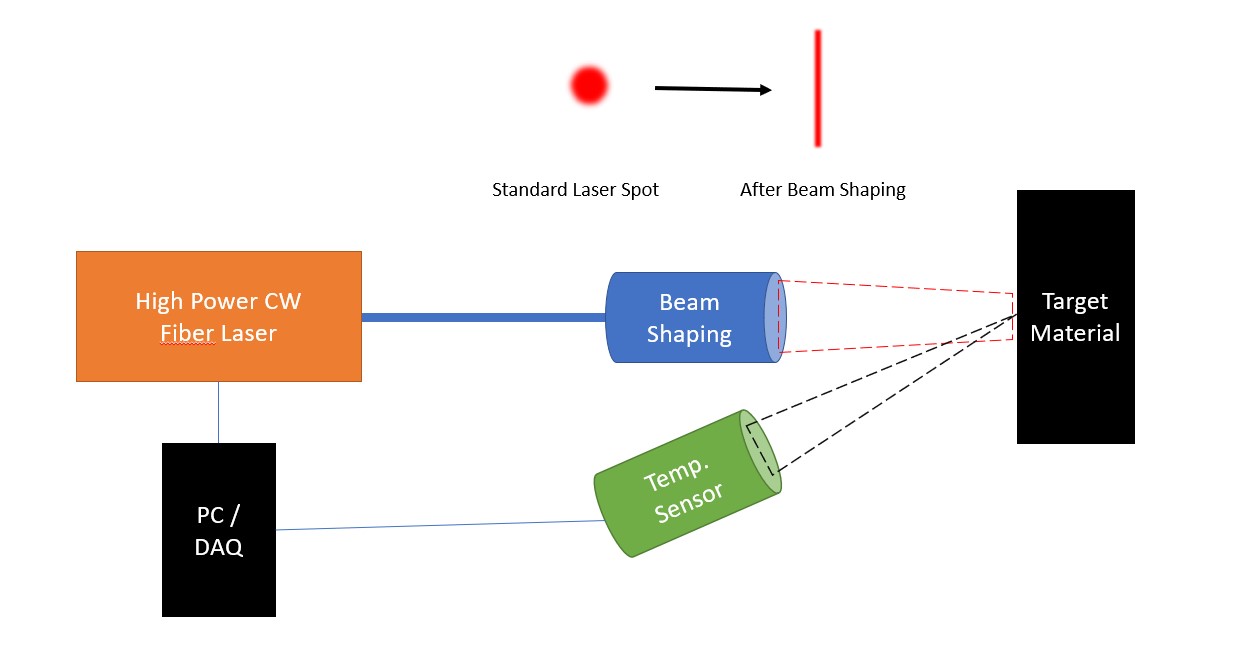

System Concept Design

System Deliverable

★ CW High power fiber laser was selected to meet the power requirement

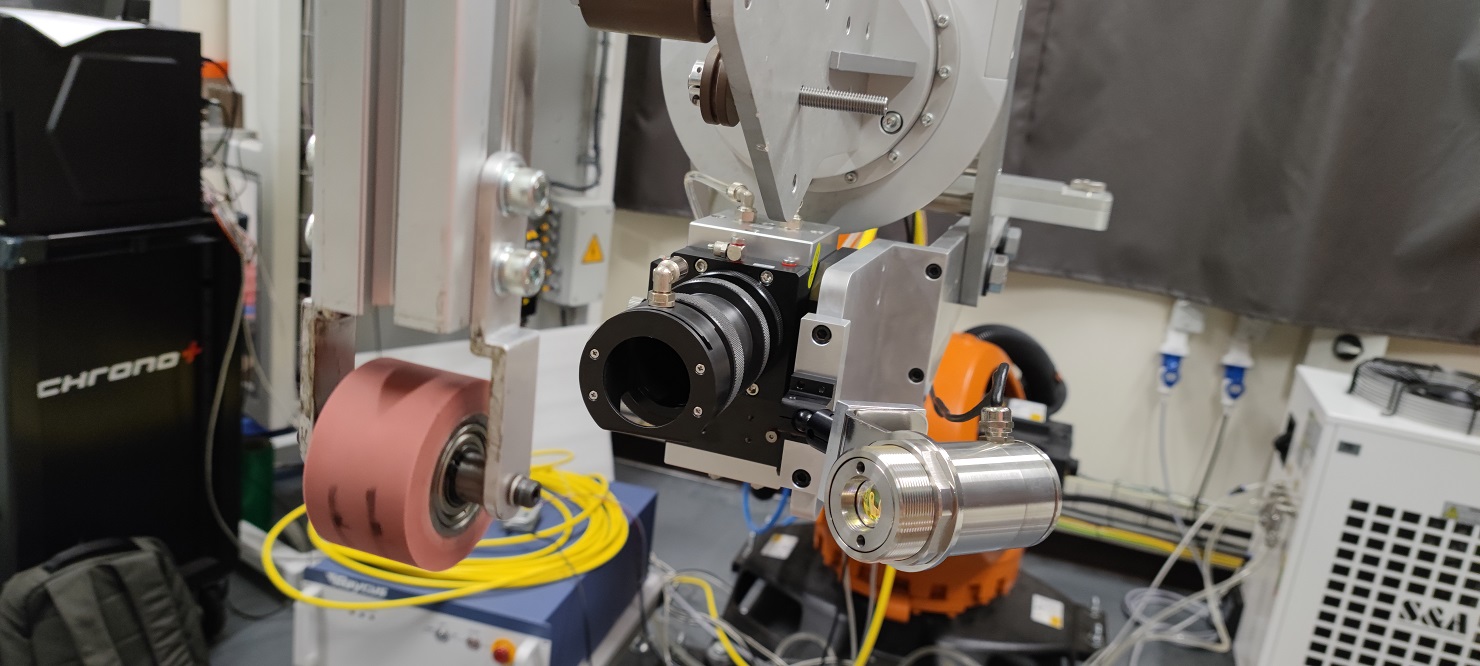

★ Customized beam shaping system was designed to meet customer laser spot requirement

★ Coling system was designed into the laser head to protect the laser head from overheating during high power process

★ The temperature sensor and data exchange unit was integrated with the laser power controller for adjusting the power automatically

★ The vision system was set up to monitor the whole metal process

★ A safety interlock system was implemented to stop the laser if people enter the laser room during the laser processing

★ Software for control the whole system is provided

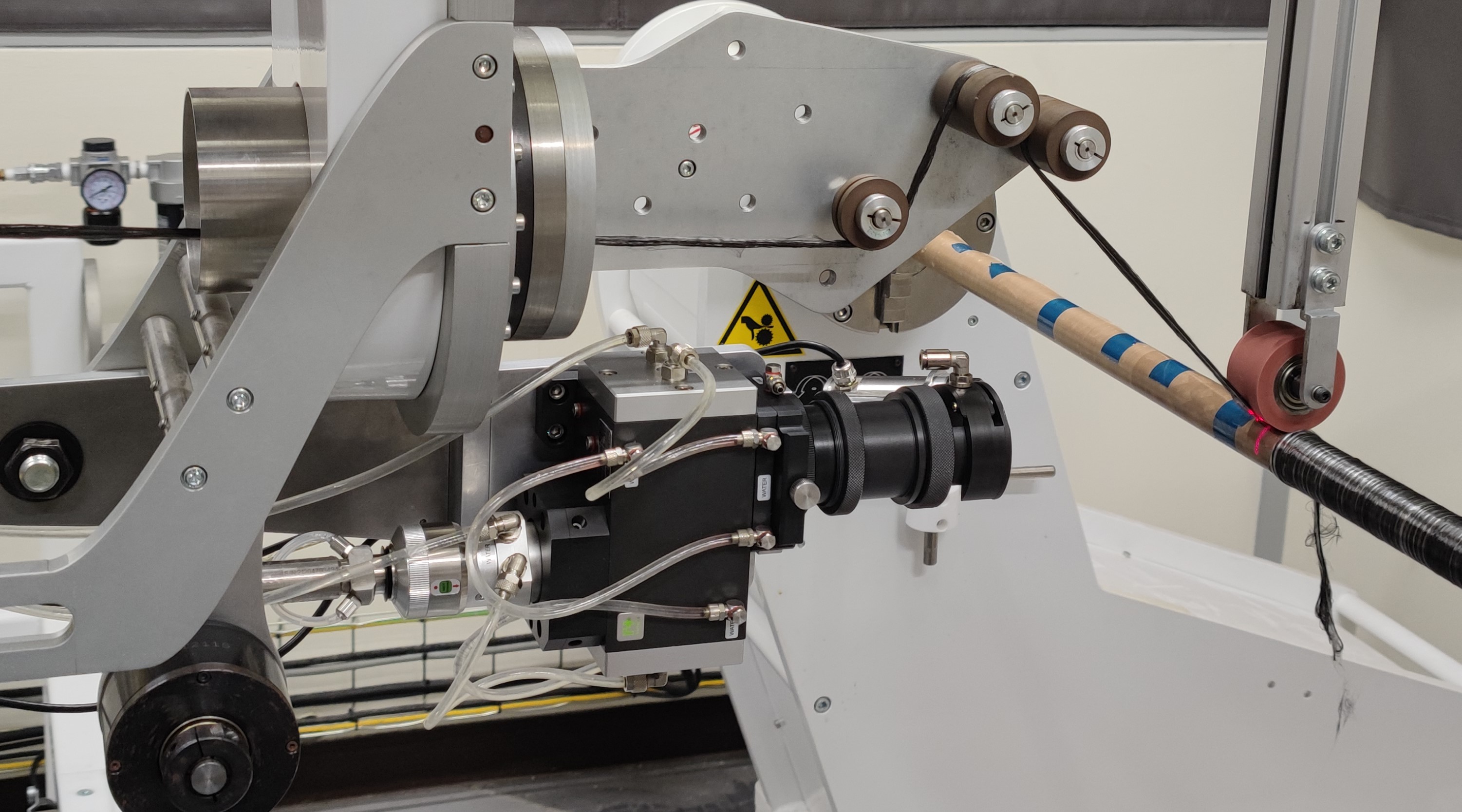

Physical Setup

Laser System Integrated with Robotic Arm

The laser beam delivery system was integrated with the customer existing robotic arm, special holding feature was designed to suit the customer's requirement to perform the heating process, the cooling system was designed into the laser head to protect the laser head from overheating during high power process

Beam Shaping and Sensing Unit

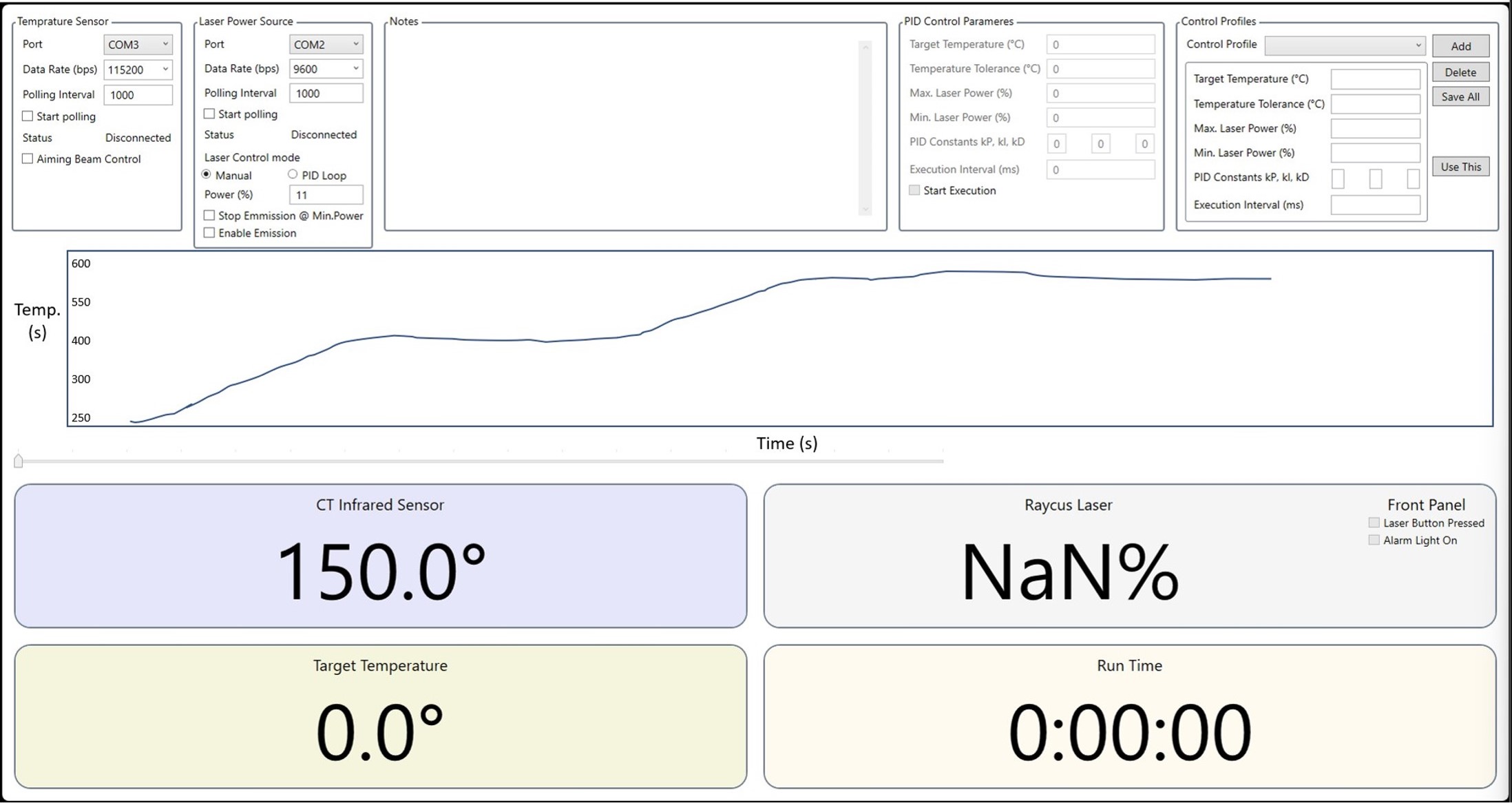

Software Features

Software Features

★ Set targeted temperature system will automatically drive the laser power and maintain the temperature

★ Set targeted laser power to maintain a constant heating power

★ Set the upper and lower limit of the temperature, the laser system will maintain the power within the range

★ Configure the PID controller based on the customer's ramping speed

★ Set different heating stages and timing,

★ Plot and save the power or temperature chart

For customized project please contact : info@simtrum.com