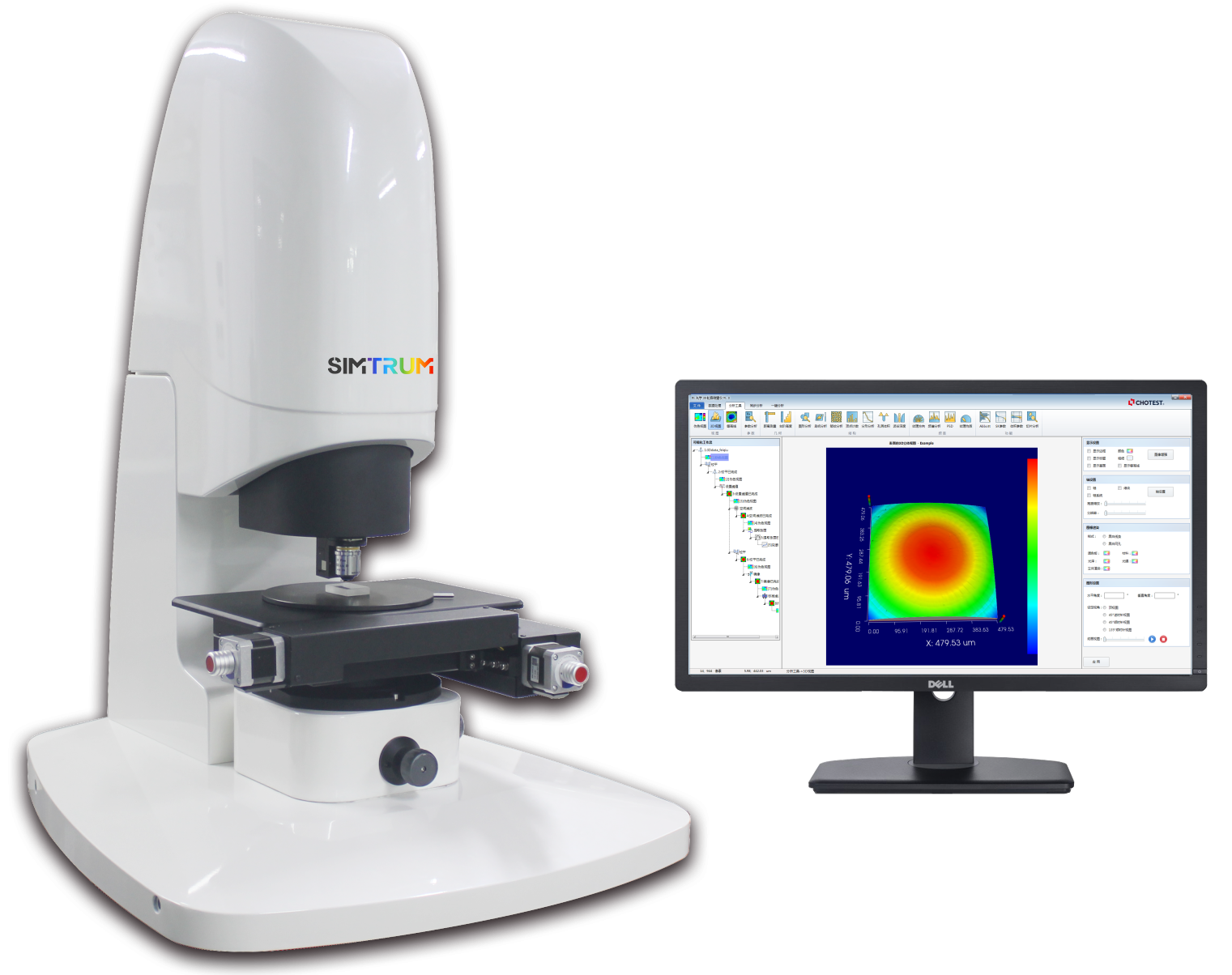

The SIMTRUM SVW1 is a user-friendly precision optical instrument with powerful analysis functions for all kinds of surface form & roughness parameters. With unique light source it could measure various precision parts with both smooth and rough surface. SIMTRUM SVW1 Optical 3D Surface profilometer is an ideal instrument for sub-Nanometer measurement of various precision parts. Based on the principle of white light interference technology, combined with precision Z-direction scanning module and 3D modeling algorithm, it contactlessly scans the surface of the object then establish a 3D image for the surface. A serial of 2D, 3D parameters reflecting surface quality of the object are obtained after XtremeVision software processes and analyzes the 3D image. |

|

| For More Information please contact us: info@simtrum.com Product Brochure: Download |

Technical Parameters

| Model No. | SIMTRUM SVW1 | SIMTRUM SVW1-Pro |

| Light Source | Green LED |

| Video System | 1024 x 1024 |

| Standard Field of View | 0.98 x 0.98 mm |

Max Field of View

| 6.0 x 6.0 mm (Optional) |

| Lens Holder | 3 holes-manual |

| XY Object Table | Size | 320 x 200 mm | 300 x 300 mm |

| Moving Range | 140 x 100 mm | 200 x 200 mm |

| Loading Capacity | 10kg |

| Control Method | Motorized |

| Tilt | ±5°Manual |

| Z Azis Focusing | Moving Range | 100 mm |

| Control Method | Motorized |

| Max Scanning Speed | 45 µm/s |

| Scanning Range of Z Axis | 10 mm |

| Resolution of Z Axis | 0.1 nm |

| Lateral Resolution | 0.1µm |

| Stage measurement | Uncertainty | 0.30% |

| Repeatability | 0.08% 1σ |

| Size | L900 x W700 x H604 mm | L900 x W700 x H700 mm |

| Weight | < 150 kg | < 160 kg |

| Power | AC100 ~ 240 V, 50/60 Hz, 4A, 300W |

Remark: Performance parameters are tested by using a 4.7µm precision master stage gauge in lab according to ISO 4287 and ISO 25178

Standard configuration

|

| Optional Configuration

|

1) Host machine

|

| 1) Parfocal objective lens: 2.5X, 5X, 10X, 50X,100X

|

2) High speed camera

|

| 2) Optical zoom: 0.75X, 1

|

3) Optical Zoom: 0.5x

|

| 3) Vacuum chuck: 4", 6" or 8

|

4) Parfocal Objective lens :10x

|

| 4) Motorized 5 holes turret

|

5) Motorized X & Y object table

|

|

|

| 6) 4.7μm stage master gauges |

|

|

7) Joystick

|

|

|

8) XtremeVision software with automatic switching function

|

| Environmental Requirement |

9) Electrical control box

|

| 1) Operating environment: No strong magnetic field |

10) Computer(WIN10) and 24" monitor

|

| 2) Working temperature:15℃~30℃, fuctuation <2℃/60min |

11) Accessory suitcase

|

| 3) Relative humidity: 5%~95% RH, no condensation

|

12) Portable inflating pump

|

| 4) Environmental vibration: VC-C or better |

13) User Manual and Product Certificate

|

| 5) Pressure supply: 0.6Mpa oil-free, water-free, 6mm diameter of hose

|

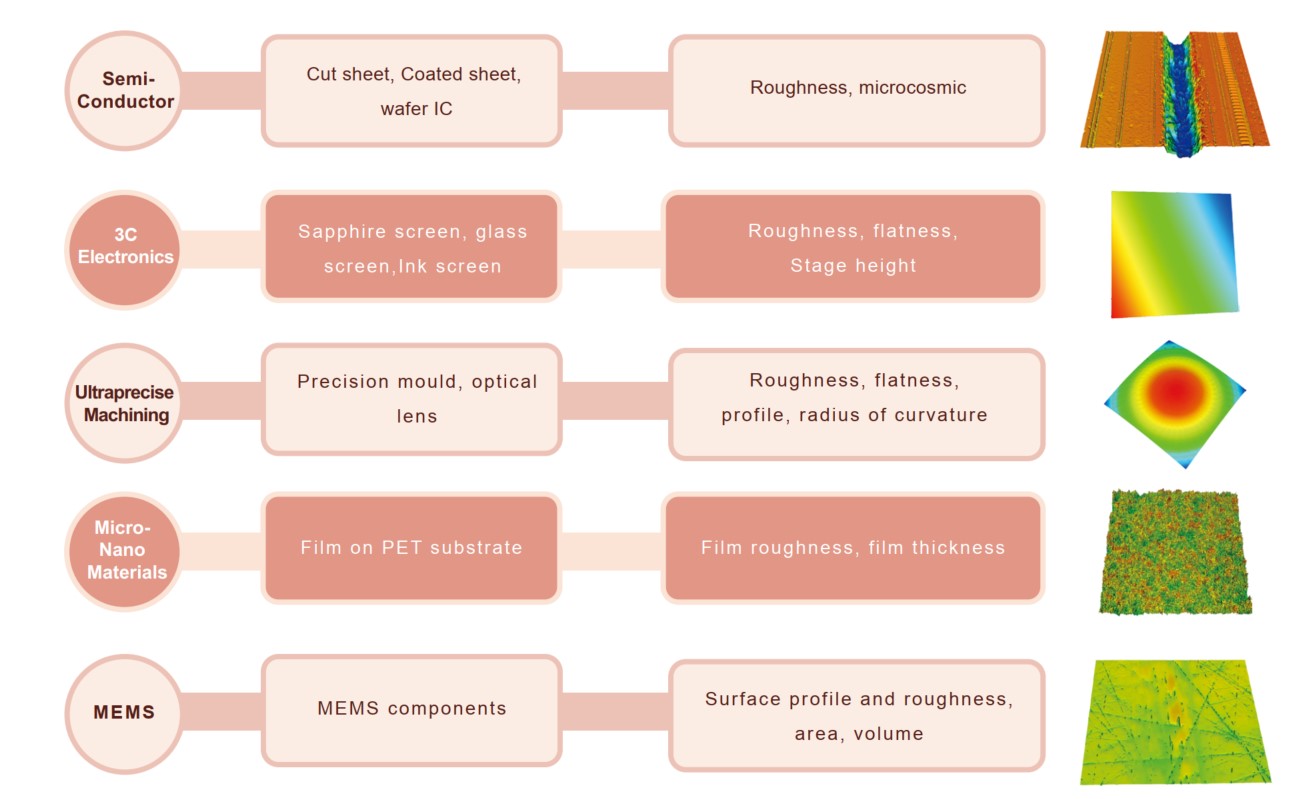

Application

It is used for measurement and analysis of surface roughness and profile of precision components from industries of semi-conductor, 3C Electronics, ultraprecise achining, optical machining, micro-nano materials, micro-electro-mechanical system.

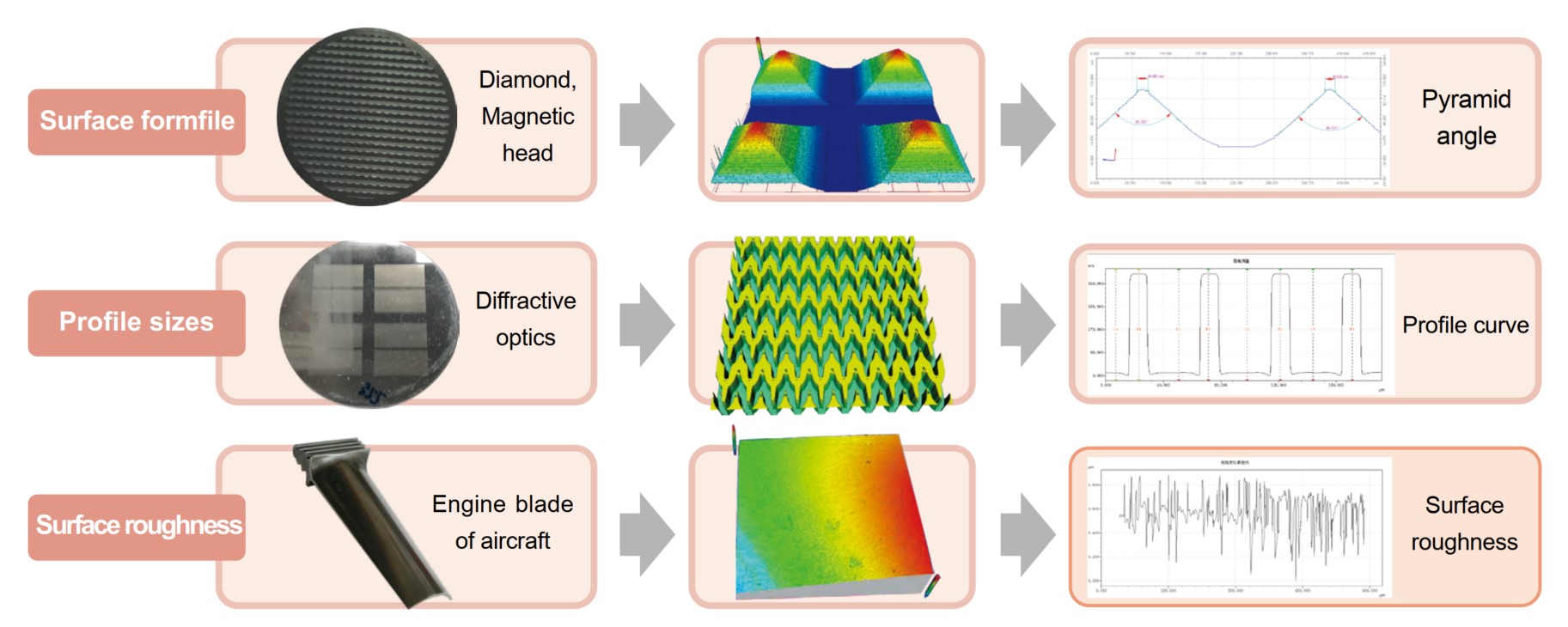

Application Case

Measurement and analysis for various products, components and materials`surface form and profile characteristics, such as flatness, roughness, waviness, appearance, surface defect, abrasion, corrosion, gap, hole, stage, curvature, deformation, etc.

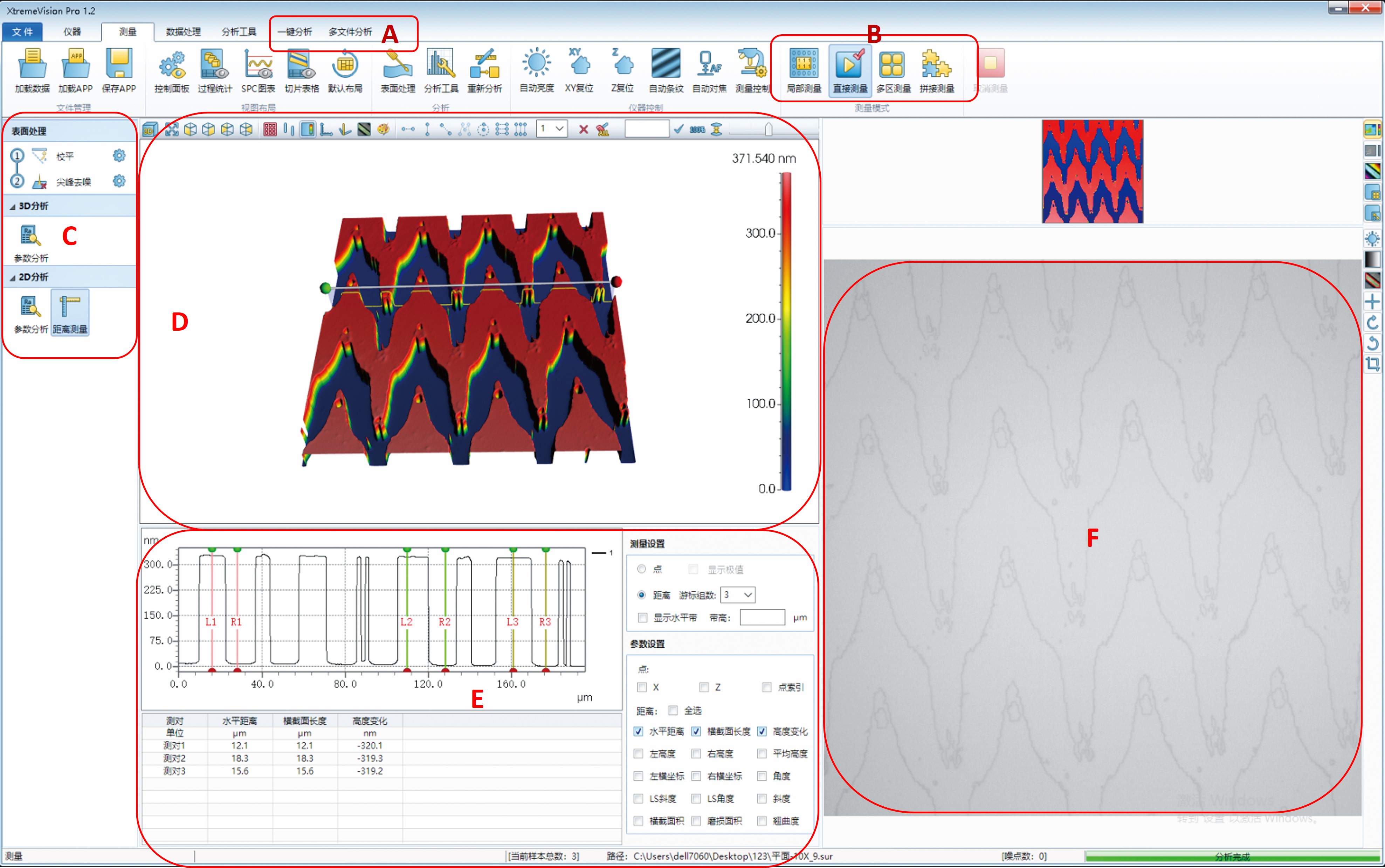

XtremeVision 3D Software

Integration software: Measurement and analysis are operated in the same interface; With pre-set analytic parameters, the software automatically generates easurement data, and achieves rapid CNC measurement.

|

| A. After set analytic program, more than 10 files can be analyzed by one click, finally data result and statistical graph are generated automatically. B. 1) Auto Measurement: After set measuring ranges & points and related parameters, multi-area can be measured. 2) Stitching Measurement: After set the measuring range and parameters, large area could be measured by one click automatically.

3) Partial measurement: Can select any area in field of view to be measured. C. Configure parameters: After pre-set leveling, filtering and 2D&3D parameters, data could be measured and generated automatically according to pre-set program.

D. 2D, 3D Image operating zone.

E. Analysis window: Display the curves and data generated by present analysis tool.

F. Real-time video window. |