|

TCSPC Testing Solution for Packaged SPAD (APD) TO46 or TO8

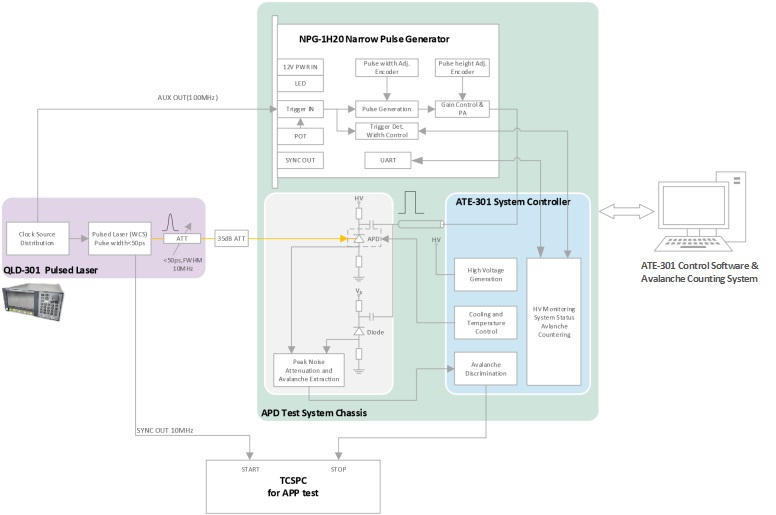

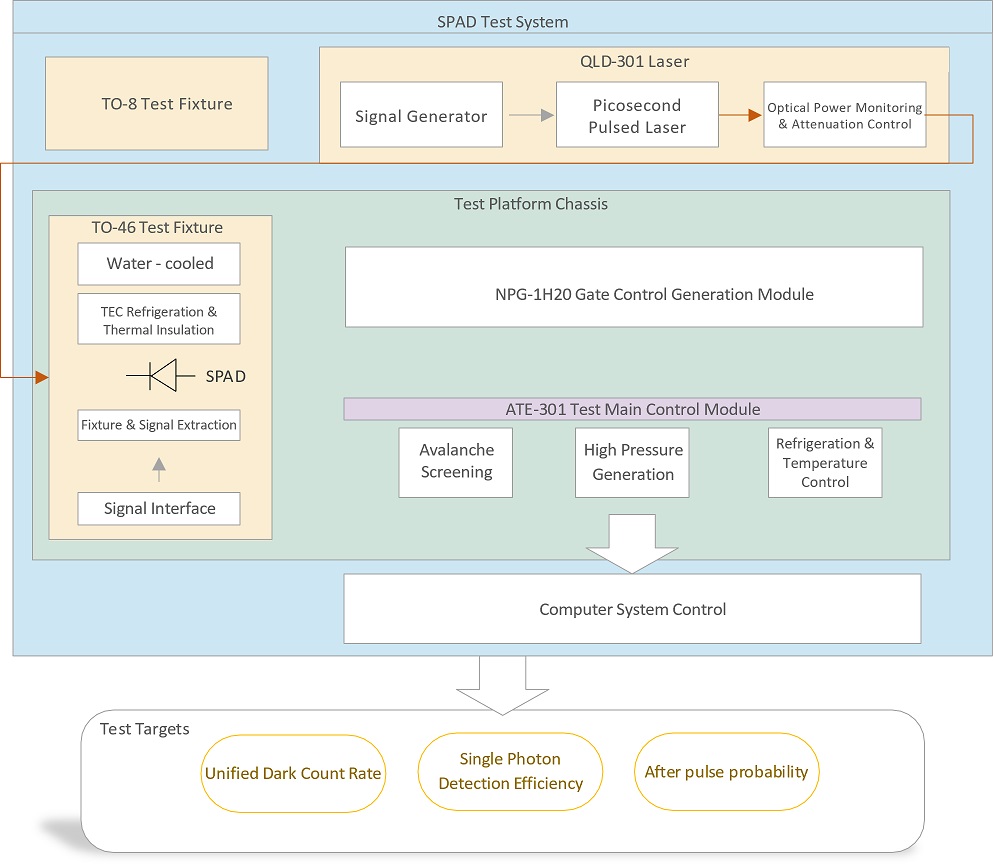

The Packaged SPAD test system is composed of picosecond pulse laser instrument QLD-301, gate control generation module NPG-1H20, test main control module ATE-301 and test chassis (including TO46 water-cooled refrigeration unit). In addition, a set of TCSPC instruments is required. Used to test post-pulse and time jitter. Among them, QLD-301 is a picosecond pulse laser with a built-in signal source, which can generate electrical and optical pulses with adjustable delay (currently an independent instrument, which can be upgraded to a module later as a chassis board);

NPG-1H20 can generate a gated pulse signal with adjustable amplitude and pulse width; the ATE-301 part contains APD correlation mode Blocks (high-pressure generation, refrigeration and temperature control, two-channel discrimination counter); the test case includes TO46 refrigeration and signal extraction unit, chassis backplane, etc., of which TO46 refrigeration and signal extraction unit includes: water cooling radiator, thermal insulation structure, TEC Refrigeration unit, spike noise suppression and signal extraction circuit, TO-46 fixture and signal interface, etc. The system composition and principle-block diagram are shown in the following figure:

Figure 1 System composition and principle-block diagram of the SPAD test platform

The QLD-301 picosecond pulsed laser includes:

● Signal generator module (Clock source distribution): It can receive an external reference clock or use an internal clock source to generate a synchronized laser pulse trigger clock and APD gated clock with adjustable relative delay. In general , the frequency of the APD gate control clock is an integer multiple of the laser trigger clock, and the system provides options of 2 times, 5 times, 10 times, 20 times, 50 times, and 100 times;

● Picosecond pulsed laser (Pulsed Laser): It can generate laser pulses synchronized with the trigger clock at the same frequency, the pulse width is less than 50ps, and the extinction ratio is greater than 40dB. In addition, the laser synchronization clock generated by it is used as the input signal of the counting module;

● Optical power monitoring and attenuation control module (ATT): control the attenuation of the laser pulse to attenuate it to the level of single photon and ensure the stability of the pulse power through high-sensitivity optical power monitoring.

NPG-1H20 gate control generation module mainly includes:

● Trigger input and monitoring unit, the trigger frequency covers 0.1~100MHz, compatible with any level trigger input;

● The gate control amplitude is adjustable, the adjustment range covers 4~6.4V, better than 100mV/step, the encoder adjustment;

● The gate width is adjustable, the adjustment range covers 0.5~2ns, 10ps/step, and encoder adjustment.

ATE-301 test main control module mainly includes:

● SPAD-related modules: including High Voltage Generation, Cooling and Temperature Control and other modules; the system is based on the gated quenching method so that the SPAD works in the gated mode, and in this mode, the detection efficiency, normalized dark count rate and post-pulse probability of the SPAD are tested;

● Dual channel counter module (dual channel counter): used to count the avalanche count value and can be upgraded to a coincidence counting module later, and automatically measure the post-pulse probability by synchronizing the clock with the laser to automatically find the peak and count the coincidence function.

Figure 2 Schematic Diagram of the Composition of the Scheme

TO-46 test fixture mainly has:

● Water-cooled TEC refrigeration and thermal insulation structure: using industrial grade three-stage refrigeration sheet, combined with water-cooling heat dissipation technology, temperature control of ≤-60 °C can be achieved at room temperature of 20 °C, meeting the low temperature requirements of SPAD; Minimize heat radiation and heat convection.

● SPAD fixture and analog front end: It adopts unique pure copper heat conduction fixture and high-speed balanced differential technology to support SPAD in TO-46 package (maximum outer diameter 6mm, package structure is shown in Appendix 1), and the structure is easy to replace; High suppression of spike noise, which can effectively extract the avalanche signal of SPAD;

● Signal interface: including optical pigtail exit, RF coaxial and DB9 interface, which are used to transmit single-photon signal, gated input signal, avalanche output signal and high voltage and temperature control interface of the system host respectively.

Performance

The specific performance index parameters are shown in the table below.

|